In the world of plastic manufacturing, choosing the right delivery system for molten resin is just as important as the part’s design.

While traditional Cold Runner systems solidify along with the part and must be removed as scrap, a Hot Runner system is a sophisticated, heated assembly that keeps plastic in a molten state throughout the entire molding process.

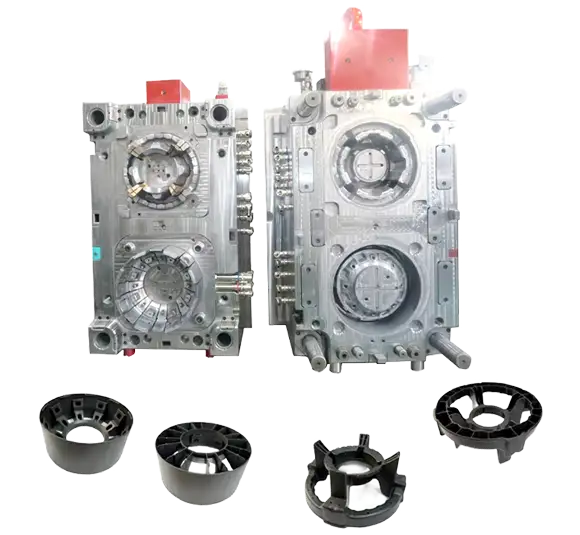

Think of it as a “heated circulatory system” for the mold. By maintaining the plastic at its ideal processing temperature, the material never solidifies within the runner channels, allowing it to be injected directly into the part cavity without creating waste.

How a Hot Runner System Works

The core function of a hot runner is to transport molten plastic from the injection molding machine’s nozzle directly to the mold cavities. Unlike a cold runner, where the plastic in the distribution channels cools and hardens every cycle, the hot runner channels are internally or externally heated.

The process follows these steps:

- Melt Delivery: Molten resin enters the Inlet (or sprue bushing) of the hot runner.

- Distribution: The resin travels through a Manifold, a heated block that branches out to multiple paths.

- Injection: The plastic reaches the Hot Nozzles (often called “drops”), which deliver the melt into the individual part cavities through a Gate.

- Cooling: While the part inside the cavity cools and solidifies, the plastic inside the manifold and nozzles remains liquid, ready for the next shot.

Key Components

A hot runner system is an intricate assembly of thermal and mechanical parts:

- Heated Manifold: The “heart” of the system. It uses electric heating elements (tubular or cartridge heaters) to maintain a consistent temperature across all flow channels.

- Nozzles: These connect the manifold to the gates. They must provide precise thermal control right up to the point of entry into the cavity.

- Temperature Controller: A standalone unit that monitors thermocouples within the manifold and nozzles to ensure the temperature stays within a narrow window.

- Gating Mechanism: Thermal Gates: The plastic at the tip freezes slightly to act as a plug.

- Valve Gates: A physical needle or pin moves forward to mechanically seal the gate, providing a much cleaner finish on the part.

Advantages: Why Use a Hot Runner?

While more complex than cold runners, hot runners offer massive long-term benefits for high-volume production:

- Zero Material Waste: Since the runner never solidifies, there is no “scrap” plastic to trim, regrind, or throw away. In a 24/7 production facility, this can save hundreds of thousands of dollars in resin costs annually.

- Reduced Cycle Times: In cold runner molding, you must wait for the thick runner to cool before the mold can open. With a hot runner, you only wait for the part itself to cool, often shaving 10% to 30% off the total cycle time.

- Improved Part Quality: Because the plastic is kept at a consistent temperature and pressure, there is less stress on the material. This results in more uniform parts with fewer sink marks or flow lines.

- Automation Friendly: There is no need for robots or manual labor to separate the parts from the runners, as they come out of the mold already “finished.”

Disadvantages and Challenges

Despite the benefits, hot runners aren’t always the right choice for every project:

- High Initial Cost: A hot runner mold can cost 3 to 5 times more than a simple cold runner mold due to the complex heating components and electronics.

- Maintenance Complexity: If a heater fails or a nozzle gets clogged, the entire production line stops. Repairing a hot runner system requires specialized technical knowledge.

- Color Changes: Changing colors is much slower. Because the “old” color is still liquid inside the manifold, it must be “purged” out completely, which can take a long time compared to just swapping a cold runner.

- Heat-Sensitive Materials: Certain plastics (like PVC) can degrade if they stay hot in the manifold for too long during a machine pause.

Conclusion: When to Choose a Hot Runner

As we look at manufacturing trends in 2026, hot runners are the standard for high-volume, high-precision industries like medical devices, automotive components, and consumer packaging.

If your project requires millions of parts and thin walls, the savings in material and cycle time will pay for the expensive hot runner system in a matter of months.

However, for short-run prototypes or parts made from heat-sensitive resins, a traditional cold runner remains the more flexible and cost-effective choice.